BLDC Planetary Gear Motor

A BLDC planetary gear motor comprises a brushless DC motor and a planetary gearbox to its advantage. It is a compact and efficient power transmission solution widely used in various industries and applications.

The BLDC planetary DC gear motor is an electric motor that operates using electronic commutation, thereby reducing the need for regular maintenance and wear, resulting in a longer lifespan and improved reliability.

Products

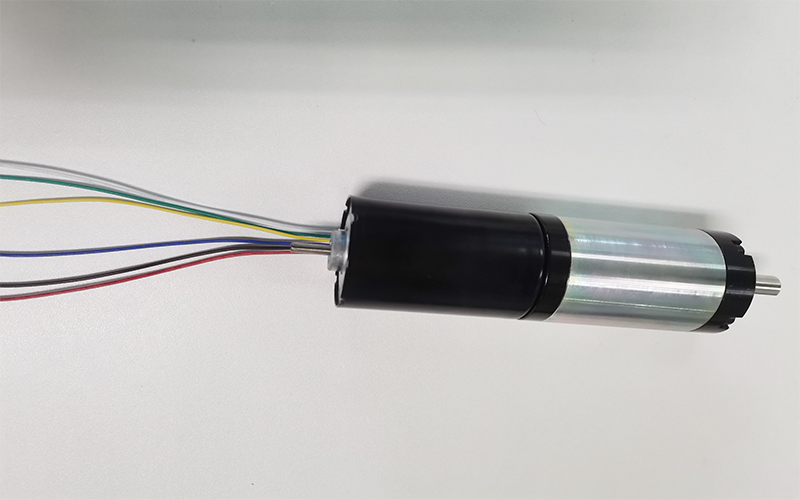

BLDC Planetary Gear Motor

Diamater:24mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque: 0.5kg.cm~7kg.cm

BLDC Planetary Gear Motor

Diamater: 24mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque: 0.5kg.cm~7kg.cm

BLDC Planetary Gear Motor

Diamater: 28mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque: 0.5kg.cm~15kg.cm

BLDC Planetary Gear Motor

Diamater: 28mm

Voltage: 6V~24VDC

Speed: 3RPM~1500RPM

Torque: 0.5kg.cm~16kg.cm

BLDC Planetary Gear Motor

Diamater: 36mm

Voltage: 12V~24VDC

Speed: 3RPM~1500RPM

Torque: 1kg.cm~30kg.cm

BLDC Planetary Gear Motor

Diamater: 36mm

Voltage: 12V~24VDC

Speed: 3RPM~1500RPM

Torque: 1kg.cm~60kg.cm

BLDC Planetary Gear Motor

Diamater: 42mm

Voltage: 12V~24VDC

Speed: 4RPM~800RPM

Torque: 1kg.cm~62kg.cm

Benefits of DC gear motor

- High Torque, High Detent Torque, High RPM, Low Noise, Small Backlash, High Precision

- Durable and High efficiency, Small Cogging Torque

- Compact size, Customized Shaft direction

- High Durability, Waterproof, Long Lifespan

- Higher Speed Range, buit-in Driver

Why Choose DONGMING MOTOR

Innovative R&D Engineering for Your Project

- Considering the rationality and convenience of the production process from the design stage.

- If our existing “standard” DC gear motor cannot provide the optimal performance, we R&D team will work with you to develop customized DC gear motor solution.

Modernized High Volume Manufacturing

4+ semi-automatic production lines, 2400000PCS DC gear motors/month

Quality & Reliability Policy

- Considering the rationality and convenience of the production process from the design stage

- Adopting the international advanced quality management system, strict management of IQC, production and QA

Effective Communication and Collaboration

- Customer needs analysis team respond to customer quickly and professionally

- Professional sale engineers provide one-stop customized services

Professional R&D engineer team work for you

From developing&research, prototype, testing, small batch test, mass production and after-sales service

Start the Custom Service for Your Project

Requirements discussion

To ensure providing the best solution of DC gear motor, the sales engineers should discuss with customer some important infomation including:

- The installation dimension for DC gear motor

- The parameter for DC gear motor includes operation load speed, operation load torque, voltage, output load current,stall torque, stall current, work cycle, working condition, noise level, lifetime,Electromagnetic shielding, etc

- The certification requirements, such as CE, ROHS, SGS, TEACH.

- The target cost and project plan.

Project Evaluation

According customer’s requirments for DC gear motor and other information of project, our R&D team analyst and evaluate the project. And to confirm provide our exsiting solution or build a new solution. If to design a new DC gear motor, DONGMING design team will provide the project evaluation report for the development time, mold cost and risk.

Prototype sample manufacturing

To confirm all requirements with customers step by step, our R&D will utilize the design software to design a product or set a 2D/3D drawing for DC gear motor.

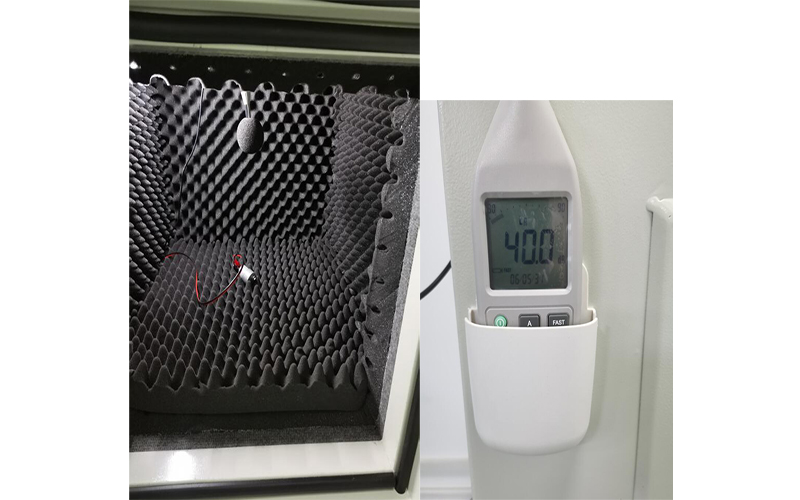

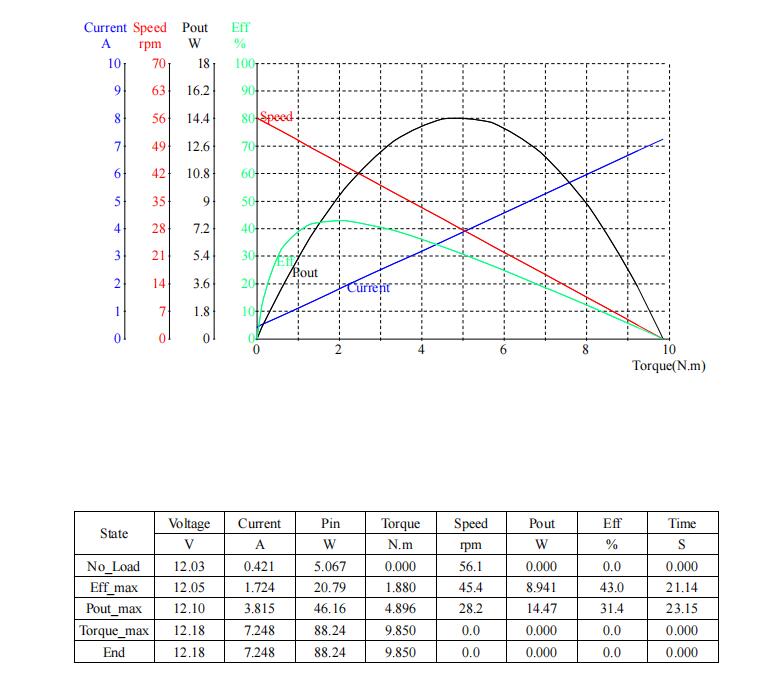

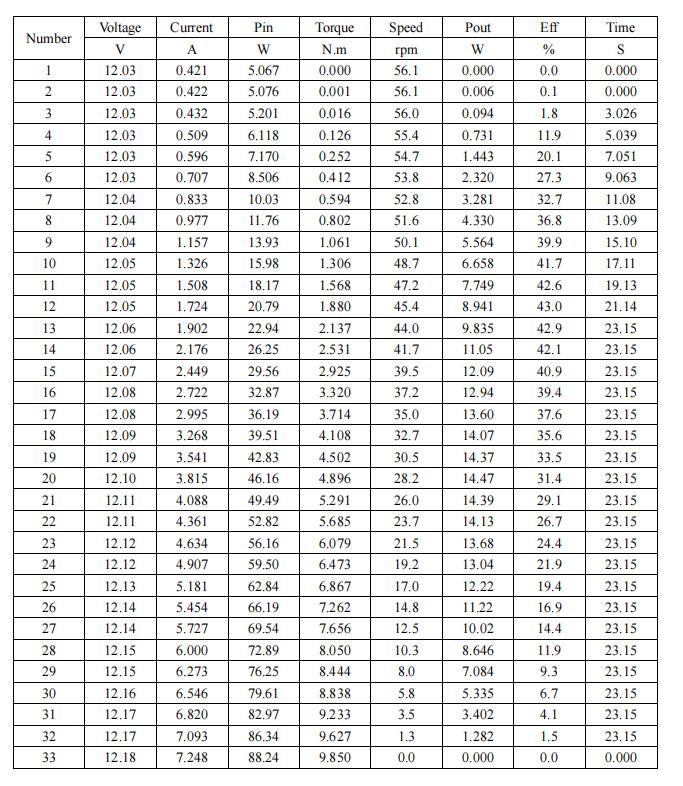

Sample performance test

When the sample is completed, our R&D team will test the DC gear motor’s all performance with our precise test equipment. If customers have lifetime requirement, we will provide the lifetime cycle test in laboratory.

Small batch production and mass production

Start a trial production after sample working perfectly on product. Launch small batch to test customers’ market.

Finally start the mass production

We have the compeleted quality control system for production.

Delivery and after-sales service

When products ready to ship, we are also responding for logistics to make sure customer picks up all products satisfied.

If customers have any issue after sales, our team will support to solve it always.

DC Motor Types

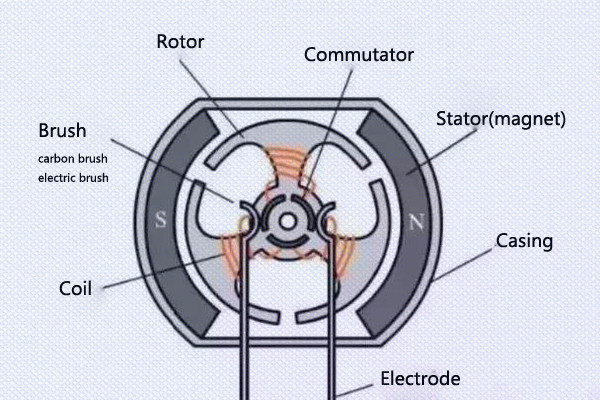

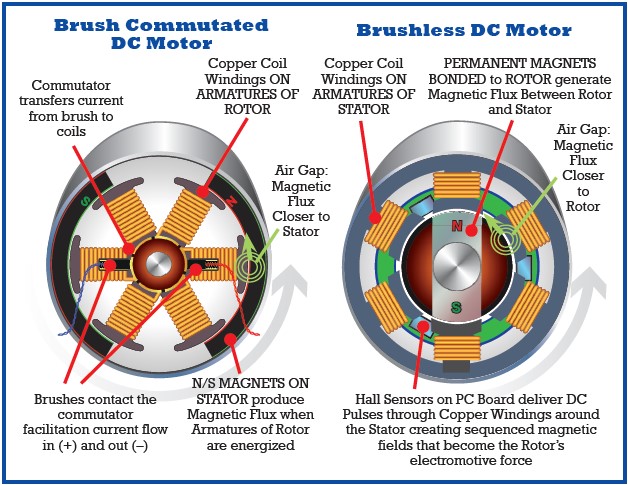

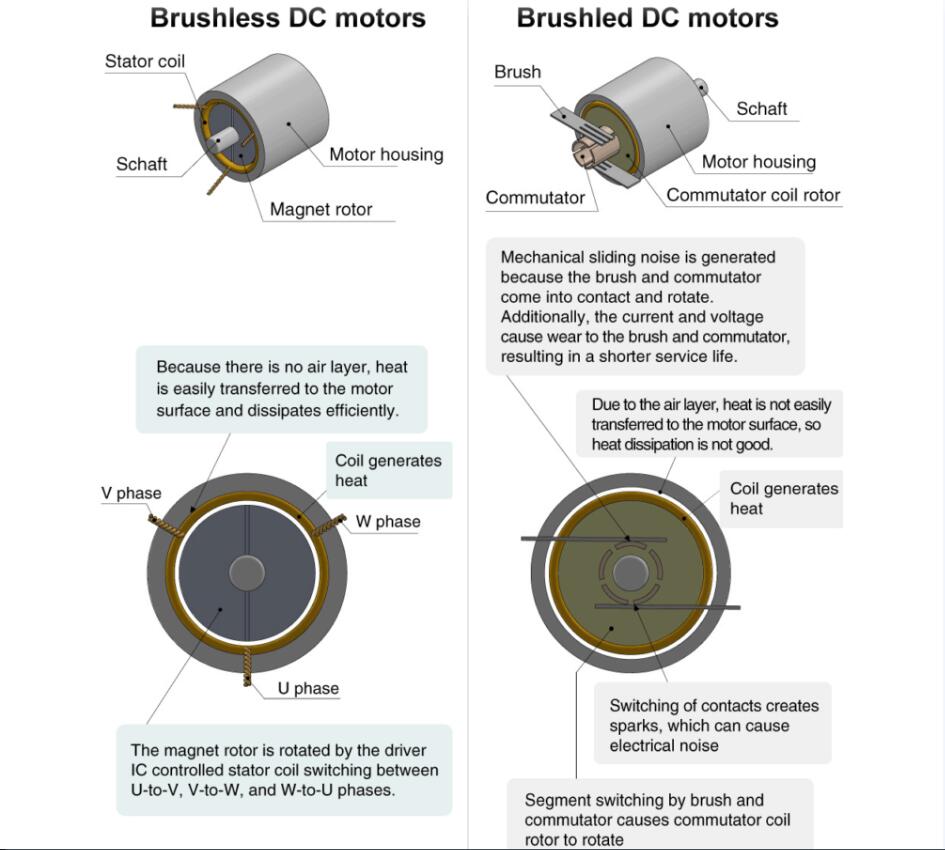

Brushed DC Motor

Brushed DC motors work by having the coil rotate inside the surrounding magnets. The rotation of the coil causes the contact between commutator and brush to alternate, therefore switching the current flow through the coil. As a result, the brushed DC motor can operate.

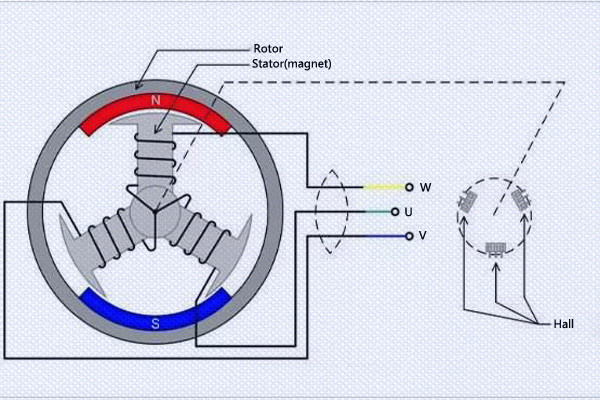

Brushless DC Motor

A Brushless DC Motor (BLDC) is an electric motor powered by a direct current voltage supply and commutated electronically instead of by brushes like in conventional DC motors. BLDC motors are more popular than the conventional DC motors nowadays, but the development of these type of motors has only been possible since the 1960s when semiconductor electronics were developed.

Gearbox Types

Spur Gearbox

Spur gears are used in mechanical applications to increase or decrease the speed of a device or multiply torque by transmitting motion and power from one shaft to another through a series of mated gears.Spur gears are more efficient compared to helical gears with the same size. They are quite reliable and offer constant velocity. Spur gears are also considered a member of positive transmission because they don't have any slippage

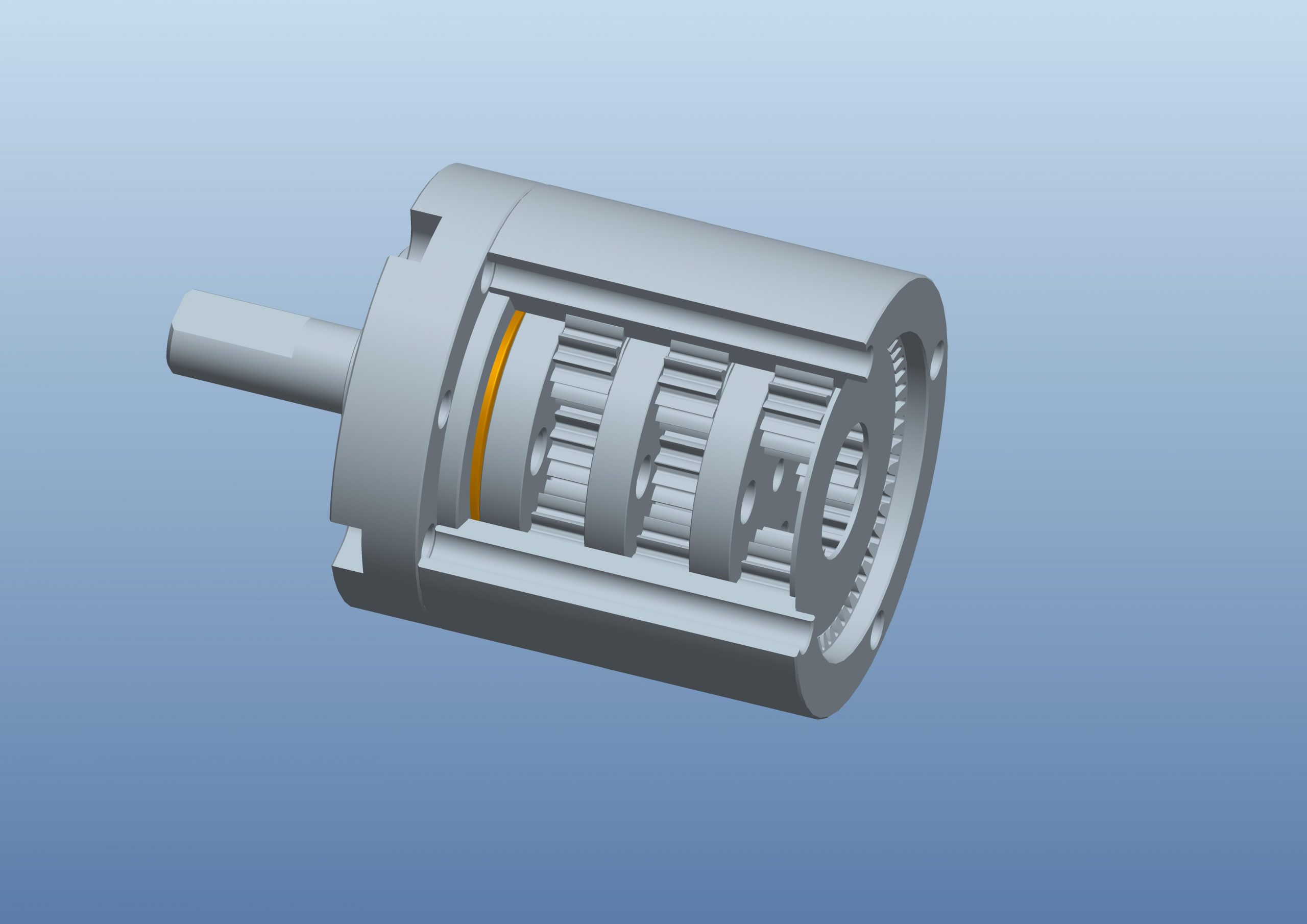

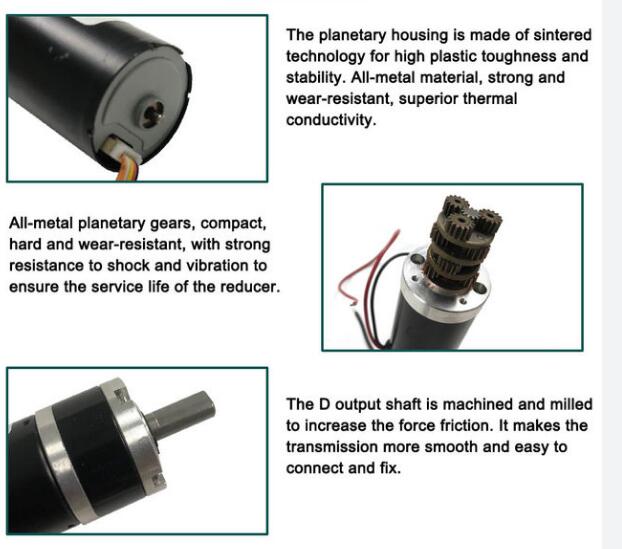

Planetary Gearbox

A planetary gearbox is a gearbox with the input shaft and the output shaft aligned. A planetary gearbox is used to transfer the largest torque in the most compact form (known as torque density).Planetary gear systems are able to produce a lot of torque because the load is shared among multiple planet gears. This arrangement also creates more contact surfaces and a larger contact area between the gears than a traditional parallel axis gear system.

Worm Gearbox

Worm gears operate by the friction created by turning lubricated gears. The friction is then converted into heat. By producing a low speed and high-speed torque level, worm gears are utilised as speed reducers, which implies that they are ideal for several applications. In theory, a worm gear is self-locking when the static friction angle is larger than the helix angle of the worm. The static friction angle is described as the angle where the load above will start to move.

Applications

Robotics

From robotic arms to teaching robotics and robotic toys, BLDC planetary gear motors play a crucial role in facilitating precise and controlled movements.

Sanitary Automations

In dispensers, lid openers, and sensor sanitary bins, BLDC planetary gear motors contribute to the seamless functioning of sanitary automation systems.

Safe and Security Systems

Electronic locks, door locks, safes, and latch closers benefit from the reliability and efficiency of BLDC planetary gear motors.

Valve/Meter Mechanisms

Electric valves, gas meters, and water meters leverage BLDC planetary gear motors for optimal performance.

Curtain Automation

Electric curtains and blinds are enhanced with the controlled and efficient movement provided by BLDC planetary gear motors.

Coffee Machines

In the realm of coffee machines, including coffee makers and bean grinders, BLDC planetary gear motors ensure precise and reliable operations.

Pet Care Devices

From anti-bark devices to pet feeders and door openers, BLDC planetary gear motors contribute to the comfort and well-being of our furry friends.

Bank Automation

ATMs, coin counters, coin selectors, coin validators, and banknote counters benefit from the precision and durability of BLDC planetary gear motors.

Vending Machines

Beverage vending machines, hot and cold drink dispensers, and juicer makers rely on the efficiency and reliability of BLDC planetary gear motors.

Medical Care Equipment

Diagnostic equipment, medical beds, massagers, and beauty care appliances are empowered by the precision movements of BLDC planetary gear motors.

Others

From BBQs and 3D printing to baby cradles, fish feeders, humidifiers, and range hoods, BLDC planetary gear motors find applications in a diverse array of industries and products.

BLDC Plantary Gear Motor Knowledge Guide

BLDC Planetary gear motor: Types, Features, and Functions

A BLDC planetary gear motor comprises a brushless DC motor and a planetary gearbox to its advantage. It is a compact and efficient power transmission solution widely used in various industries and applications.

The BLDC planetary DC gear motor is an electric motor that operates using electronic commutation, thereby reducing the need for regular maintenance and wear, resulting in a longer lifespan and improved reliability.

Using electronic commutation, Brushless DC gear motors don’t need brushes and commutators. Instead of brushes, BLDC motors incorporate a controller that precisely controls the switching of current to the motor windings. This electronic commutation reduces friction and wear, allowing for smoother operation and increased efficiency.

Furthermore, the brushless design offers other benefits contributing to the extended lifespan. With fewer mechanical components, fewer points of failure result in enhanced durability. Additionally, the electronic commutation system enables better control over the motor, reducing stress on the gears and ensuring smoother and more efficient power transmission.

To recap, BLDC planetary gear motors outperform their brushed counterparts in terms of lifespan due to the utilization of brushless DC motors. Eliminating brushes and adopting electronic commutation significantly reduce wear, increase efficiency, and improve overall reliability. This makes brushless planetary gear motors a preferred choice in applications where longevity and consistent performance are essential.

Why the BLDC planetary gear motor's noise is very low?

The low noise in this unique gear system is based on the brushless motor, the planetary gear system it uses, and proper lubrication. Let’s start with the first, which is the brushless motor. This characteristic eradicates friction which is the common noise source in brushed motors. As a result, there are no brushes to wear out or generate audible vibrations during operation.

Additionally, the planetary gear system employed in these motors contributes to their low noise output. The gear arrangement distributes the torque across multiple gears, reducing the load on each gear tooth. This helps to minimize gear rattling and vibrations that could otherwise generate noise.

Proper lubrication is essential for minimizing the noise generated by a DC planetary gear motor. Applying the appropriate lubricant to the gears and bearings can reduce friction and wear, resulting in smoother and quieter operations. The lubrication forms a protective film between the gear teeth, preventing metal-to-metal contact and dampening vibrations. It also helps to dissipate heat, maintaining optimal operating conditions. Regular lubrication maintenance ensures the motor operates quietly and efficiently, prolonging its lifespan and enhancing overall performance. Choosing a high-quality lubricant for gear applications can significantly reduce noise and improve the overall user experience.

Furthermore, brushless motors typically utilize electronic commutation, which is more precise and efficient than brushed motors’ mechanical commutation. This electronic commutation results in smoother operation and reduced vibration, further contributing to the low noise level of BLDC planetary gear motors.

The combination of brushless technology, planetary gear design, and electronic commutation enables these motors to operate with minimal noise, making them suitable for applications where quiet operation is desired or required.

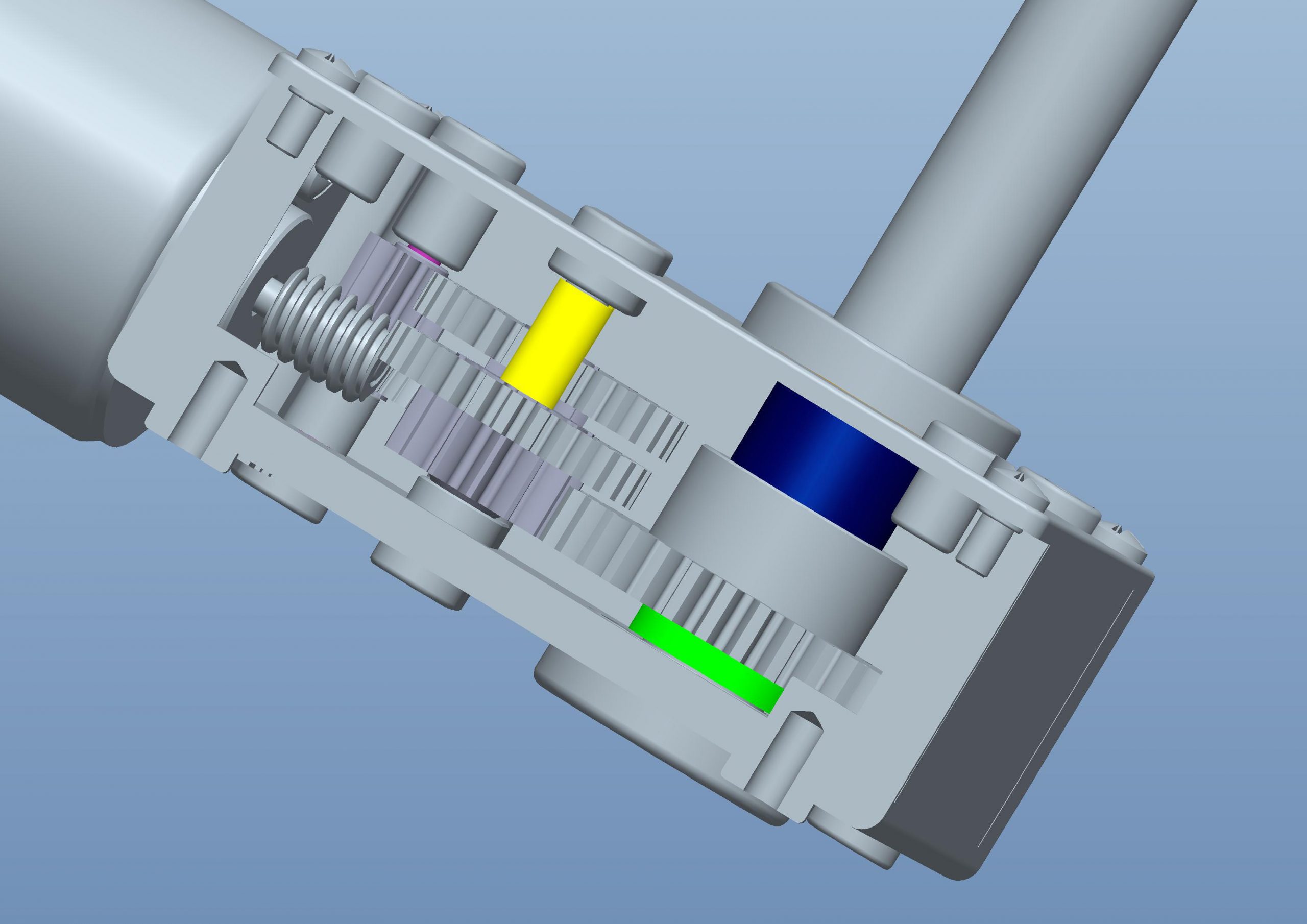

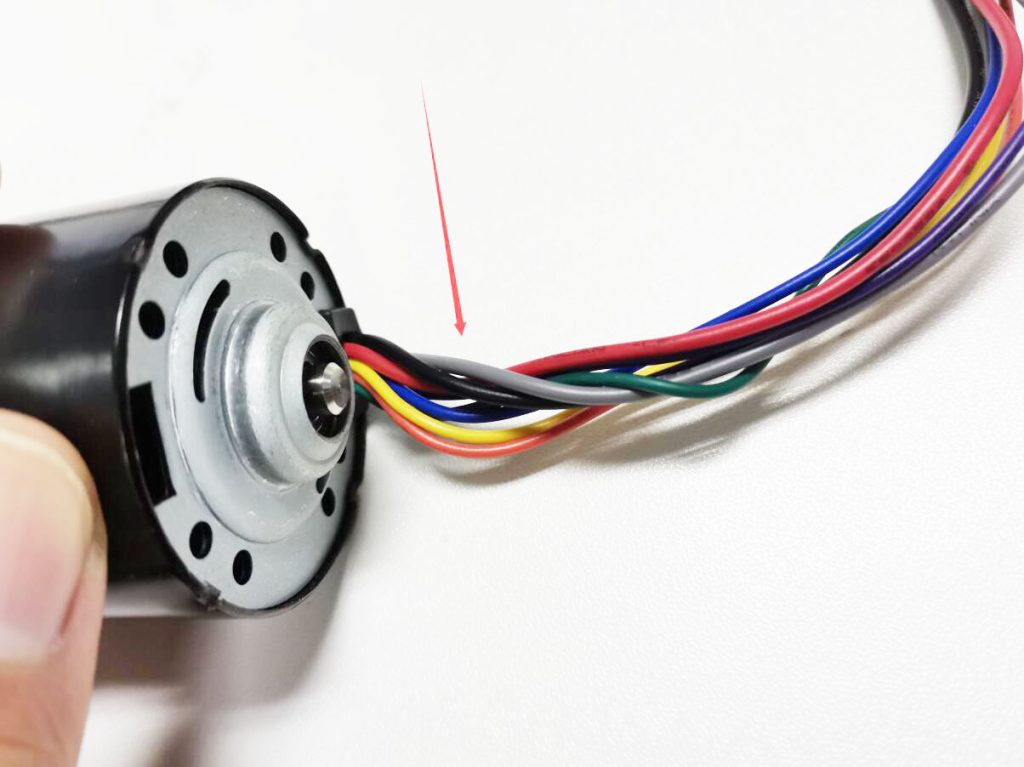

How BLDC Planetary Gear Motor built-in driver works?

A BLDC planetary gear motor is a compact and efficient motor whose torque output is high and offers smooth operation and precise control. The motor is driven by a built-in driver, which plays a crucial role in its operation.

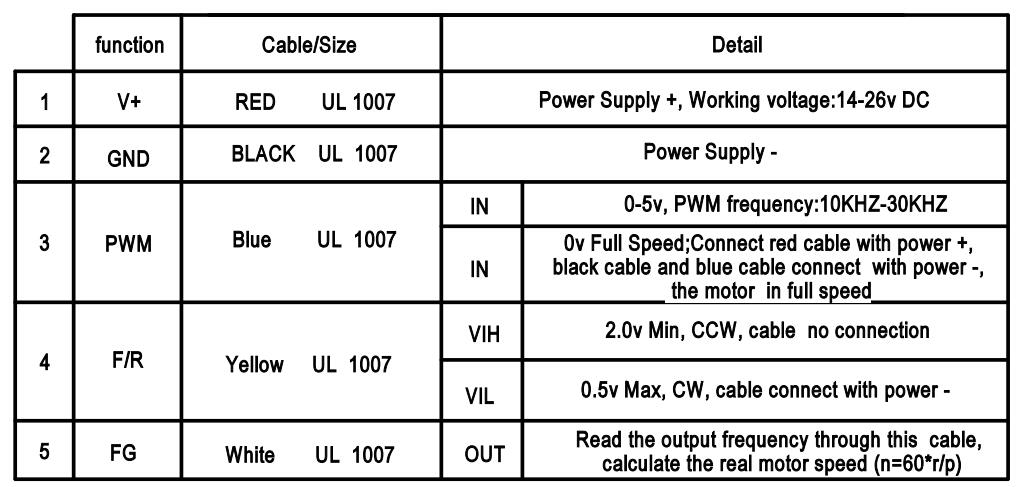

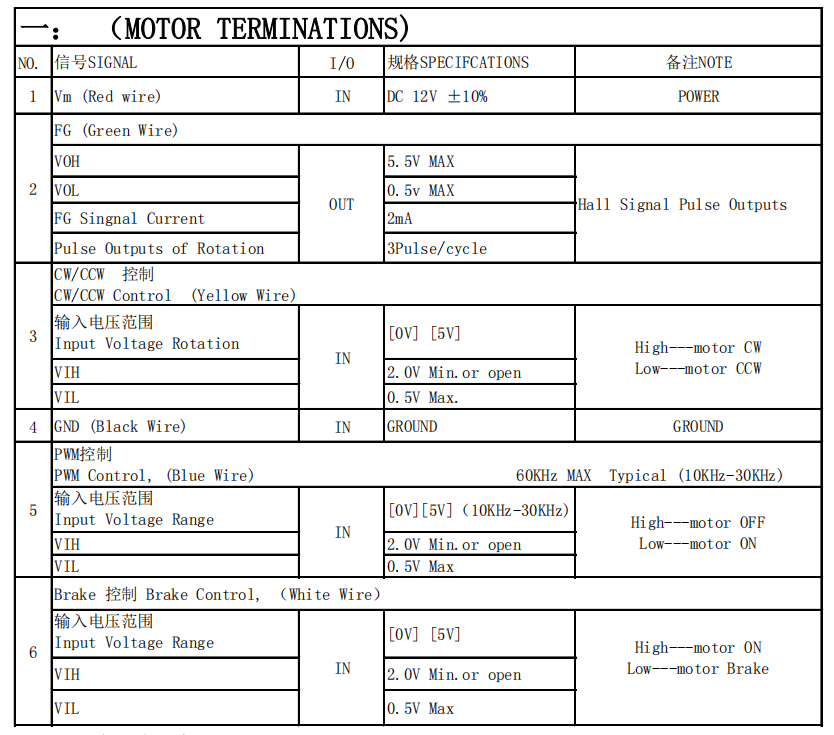

The built-in driver of a BLDC planetary gear motor controls the motor’s speed, direction, and other parameters. It receives power through the power supply cables consisting of positive (+) and negative (-) terminals. These cables provide the necessary voltage and current for the motor’s operation.

The direction control cables, often called CW (clockwise) and CCW (counterclockwise), enable the driver to change the motor’s rotational direction while the PWM control cable allows the driver to modulate the motor’s speed by adjusting the pulse width modulation signal. By controlling the current flow through these cables, the driver can determine the desired direction of rotation and regulate the motor’s speed.

The signal feedback cable transmits information about the motor’s rotational speed, position, and other feedback data. This feedback helps the driver adjust and optimize the motor’s performance.

Lastly, the brake control cable is responsible for activating the brake mechanism in the motor. When the brake control signal is applied, the motor stops quickly and securely.

To sum it up, the built-in driver of a BLDC planetary gear motor integrates these cables to provide precise control and efficient operation, making it a versatile choice for various applications.

The Benefits of BLDC Planetary Gear Motor?

In the world of DC electric motors, a rising star has been making waves in various industries – the BLDC Planetary Gear Motor. This innovative motor combines the advantages of brushless technology with the efficiency and power of planetary gearing. From its small size to high power ratio to its ability to deliver high torque at low speeds, BLDC Planetary Gear Motor offer many benefits that make them indispensable in today’s diverse applications.

The versatility of brushless planetary gear motor lies in their advanced technology and their adaptability to various voltage and diameter specifications. Brushless dc planetary gear motor are available in 12V and 24V configurations, allowing engineers and designers to choose the voltage that best suits their specific applications. The choice between these brushless dc gear motor 12V and 24V brushless dc gear motor options depends on power requirements, energy efficiency, and compatibility with the surrounding electrical systems. Whether it’s a lower-voltage setup for energy-conscious applications or a higher-voltage option for tasks demanding robust performance, BLDC planetary gear motor can seamlessly integrate into diverse electrical setups.

Furthermore, the range of diameters available, spanning from a compact 16mm to a substantial 56mm, makes BLDC planetary gear motors suitable for a broader spectrum of applications. Smaller diameters planetary gear BLDC motor are ideal for limited space, such as robotics or compact machinery, where precision and efficiency are crucial. On the other hand, larger diameter options, like 42mm and 56mm, provide higher torque output, making them well-suited for applications requiring heavy-duty power, like conveyor system, Lawn mower, household oven, electric valve. This array of choices in both voltage and diameter ensures that BLDC planetary gear motor can be tailored precisely to the requirements of various industries and applications, ultimately delivering optimal efficiency and performance.

Small Size to High Power Ratio

One of the standout features of BLDC Planetary Gear Motors is their remarkable size-to-power ratio. Despite their compact dimensions, these brushless dc gear motors can deliver high power levels, making them a preferred choice in applications where space is at a premium. Whether in robotics, medical devices, or precision machinery, their ability to provide substantial power in a small package is invaluable

High Efficiency

Efficiency is a critical factor in any motor-driven application. Brushless Planetary Gear Motor excels in this department. They are known for their impressive efficiency, ensuring minimal energy is wasted during operation. This leads to energy savings and reduces heat generation, extending the motor’s lifespan while maintaining optimal performance

Good Controller Integration

Efficient control is a crucial aspect of motor applications, and Brushless gear motor offers seamless integration with controllers. BLDC planetary gear motor can be easily controlled with features such as power supply management, signal feedback, direction control (CW and CCW), PWM control, and brake control. This level of control precision is invaluable in applications where precise positioning and speed regulation are essential, including conveyor systems and automated assembly lines.

Cables Function:

Adjustable Speed

Versatility is a hallmark of BLDC Planetary Gear Motor. The brushless planetary gear motor offer adjustable speed control, allowing them to adapt to a wide range of tasks and operating conditions. Whether it’s a high-speed task or a low-speed, high-torque requirement, these motors can be easily tailored to meet specific application needs

Long Life

Investing in a motor with a long service life is a wise decision for any application. BLDC Planetary Gear Motor is engineered for durability and longevity. Their robust construction and efficient design ensure that they can operate continuously for extended periods without the risk of premature failure. This longevity translates into cost savings over time

No Spark or EMI

Safety and reliability are paramount in many industries, especially those involving sensitive electronics or hazardous environments. BLDC Planetary Gear Motor has a distinct advantage in this regard. Brushless gear motor do not produce sparks or electromagnetic interference (EMI), making them safe for use in a variety of settings. This characteristic makes them suitable for applications where EMI can disrupt delicate equipment or pose a safety hazard

Quietness

Noise pollution is a concern in many industries and environments. The quiet operation of BLDC Planetary Gear Motor is a significant advantage in noise-sensitive settings. Whether it’s a medical device, consumer appliance, or laboratory equipment, the bldc gear motor operate with minimal noise, contributing to a more peaceful and productive working environment

High Torque at Low Speeds

In many applications, the ability to deliver high torque at low speeds is a critical requirement. high torque DC brushless gear motor excels in this aspect. Their planetary gearing system provides substantial torque even at low rotational speeds, making them ideal for tasks that demand precise control and ample force

Smooth and Precise Control

In addition to their advanced control capabilities, BLDC planetary gear motor provides smooth and precise movement control. Their high-resolution feedback systems ensure accurate positioning and motion control. This makes them an excellent choice for applications where precision is paramount, such as 3D printers, camera gimbals, and telescope mounts. The ability to achieve smooth and precise movements enhances the quality of output and user experience.

Efficiency and Power Density

Efficiency and power density are crucial factors in motor selection for many applications. BLDC planetary gear motor are known for their high efficiency, converting electrical energy into mechanical motion with minimal waste. This efficiency translates into lower operating costs and reduced power consumption, making them environmentally friendly. Moreover, their compact design and high power density enable them to fit into tight spaces while delivering robust performance, making them suitable for applications with space constraints.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Reversible Direction and Easy Speed Adjustment

The versatility of BLDC Planetary Gear Motor extends to their control options. These motors can easily change direction and adjust speed as needed. The Brushless DC planetary gear motor can be used on CW or CCW. This feature simplifies their integration into various systems and enhances their adaptability to changing operational requirements

In conclusion, BLDC Planetary Gear Motor have become essential in a wide range of industries and applications. Their small size, high efficiency, adjustable speed, long life, and noiseless operation make them a top choice for engineers and designers seeking reliable and versatile motor solutions. From robotics and medical devices to automotive systems and industrial machinery, brushless planetary gear motor continues revolutionizing how we power our world. With their ability to deliver exceptional performance in a compact package, they will remain a driving force in the world of brushless DC gear motor for years to come.

How does BLDC Planetary Gear Motor works?

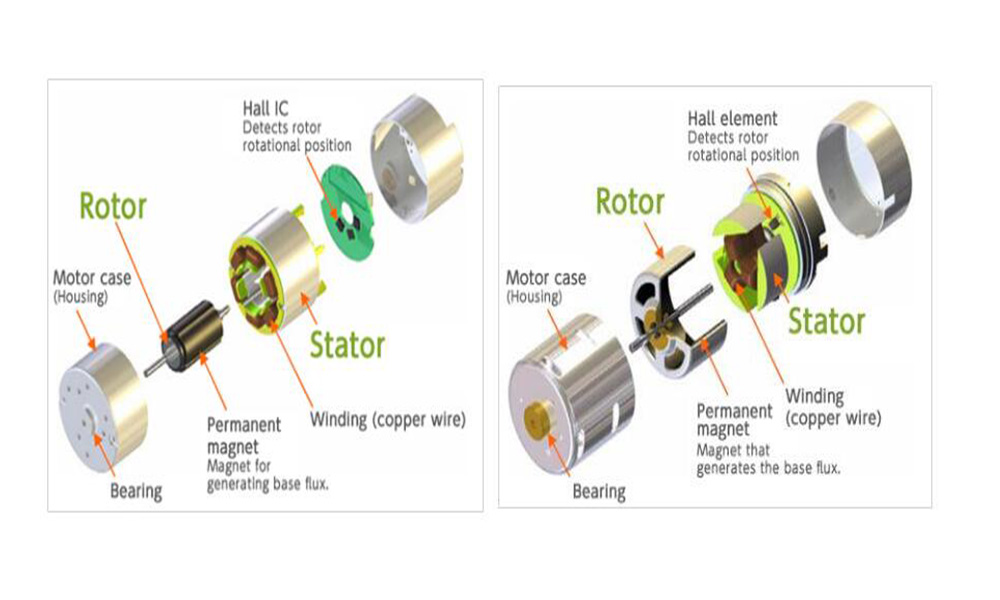

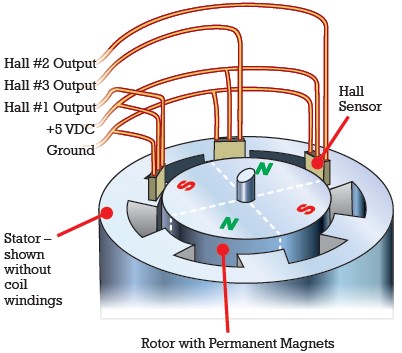

- BLDC Motor Constructionfor brushless planetary gear motor:

The brushless DC motor consists of a rotor and a stator. The rotor comprises permanent magnets, while the stator consists of windings. The windings are energized in a sequence to create a rotating magnetic field.

- Working of BLDC Motorfor BLDC planetary gear motor:

The BLDC motor converts electrical energy into mechanical energy. The electronic controller switches DC currents to the motor windings, producing magnetic fields that rotate in space. The rotor follows these rotating magnetic fields.

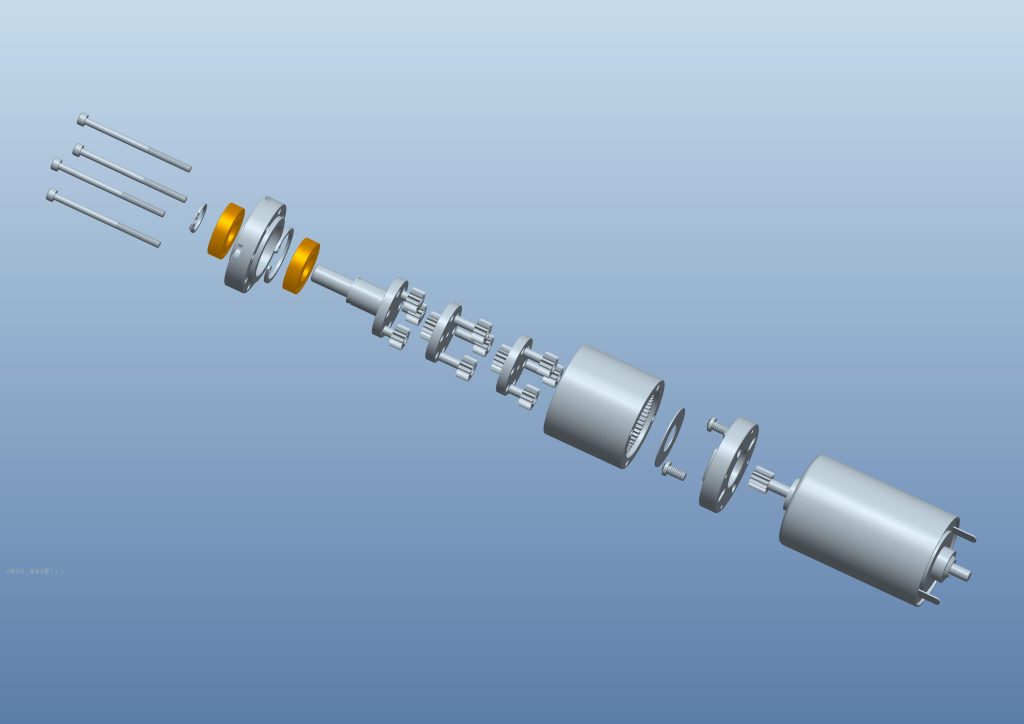

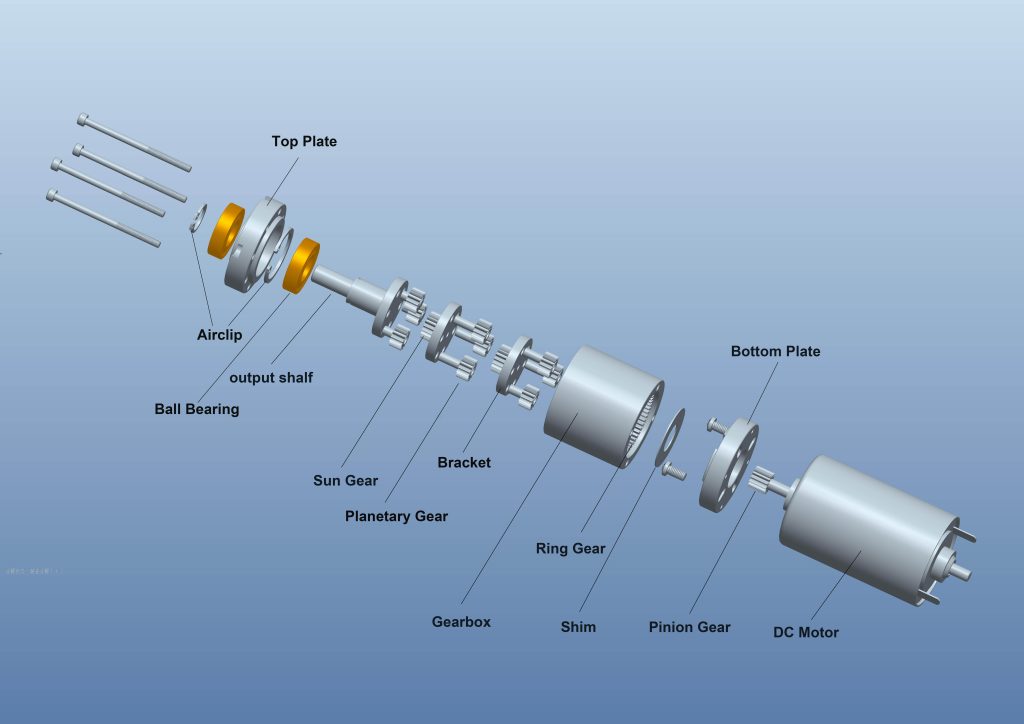

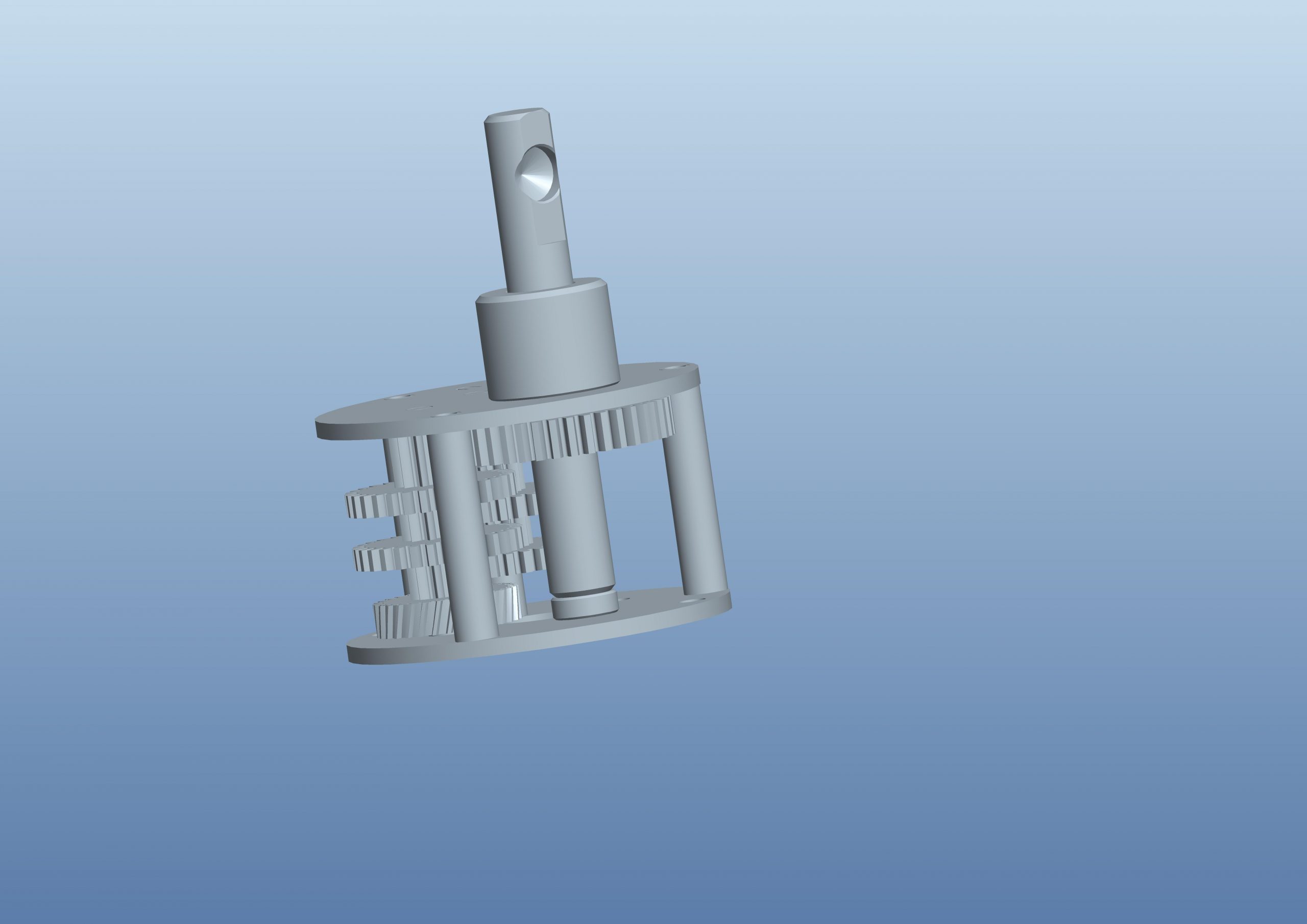

- Planetary Gearbox Constructionfor brushless planetary gear motor:

For the bldc planetary gear motor, planetary gearbox consists of three main components: a central or “sun” gear, multiple “planet” gears, and a “ring” gear. The sun gear is at the center, with planet gears orbiting around it, similar to our solar system. All these components are enclosed within the ring gear.

- Working of Planetary Gearboxfor brushless planetary gear motor:

When the sun gear (driven by the motor) rotates, it causes the planet gears to rotate as they mesh with the sun gear. The planet gears also mesh with the ring gear on the inner wall of the planetary gearhead housing. Depending on the configuration, any of these three main components – the sun gear, the planet gears, or the ring gear – can serve as the input (receiving power from an external source), output (delivering power to perform work), or can be held stationary (held fixed or immobile during operation).

- Output Shaft:

Finally, for brushless dc planetary gear motor, the mechanical energy is transmitted from the brushless DC motor to planetary gearbox, to the shaft output, controlling speed and direction.