Square Gear Motor

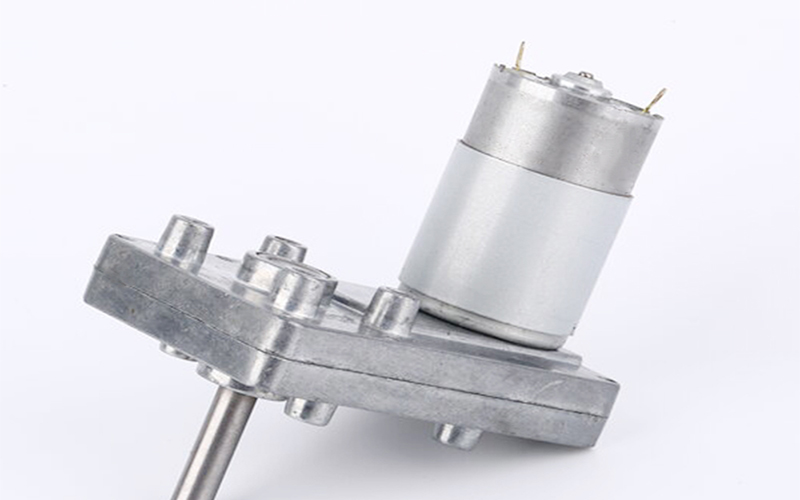

Square gear motor is a DC motor with a square gearbox which simply means that these motors equip Gearboxes for providing a great balance between torque-speed as per your requirement. This type design is to increase torque and also save space for the customer applications.

The applications of square gearbox motor are Central air conditioning valve, Amusement equipment, Coin refund devices; Peristaltic pump, ATM bank automatic system, Medical equipment, Office equipment, Household appliance, Automatic actuator and many more.

Suqare Gear Motor

DC Square Gear Motor

Diamater: 33mm

Voltage: 6V~24VDC

Speed: 5RPM~200RPM

Torque: 0.3kg.cm~13kg.cm

DC Square Gear Motor

Diamater: 34.6mm

Voltage: 6V~24VDC

Speed: 5RPM~200RPM

Torque: 0.3kg.cm~14kg.cm

DC Square Gear Motor

Diamater: 34.6mm

Voltage: 6V~24VDC

Speed: 5RPM~200RPM

Torque: 0.3kg.cm~15kg.cm

DC Square Gear Motor

Diamater: 34.6mm

Voltage: 12V~24VDC

Speed: 5RPM~200RPM

Torque: 0.3kg.cm~19kg.cm

DC Square Gear Motor

Diamater: 34.6mm

Voltage: 6V~24VDC

Speed: 3RPM~150RPM

Torque: 1kg.cm~32kg.cm

DC Square Gear Motor

Diamater: 34.6mm

Voltage: 6V~24VDC

Speed: 3RPM~150RPM

Torque: 1kg.cm~45kg.cm

DC Square Gear Motor

Diamater: 37.6mm

Voltage: 12V~24VDC

Speed: 2.5RPM~137RPM

Torque:1kg.cm~100kg.cm

DC Square Gear Motor

Diamater: 36mm

Voltage: 12V~24VDC

Speed: 2RPM-60RPM

Torque: 1kg.cm~120kg.cm

DC Square Gear Motor

Diamater: 36mm

Voltage: 12V~24VDC

Speed: 5RPM-15RPM

Torque: 1kg.cm~80kg.cm

Benefits of Suqare Gear Motor

- High Torque, High Detent Torque, High RPM, Low Noise, Small Backlash, High Precision

- Durable and High efficiency, Small Cogging Torque

- Compact size, Customized Shaft direction

- High Durability, Waterproof, Long Lifespan

- Higher Speed Range, buit-in Driver

Why Choose DONGMING MOTOR

Innovative R&D Engineering for Your Project

- Considering the rationality and convenience of the production process from the design stage.

- If our existing “standard” DC gear motor cannot provide the optimal performance, we R&D team will work with you to develop customized DC gear motor solution.

Modernized High Volume Manufacturing

4+ semi-automatic production lines, 2400000PCS DC gear motors/month

Quality & Reliability Policy

- Considering the rationality and convenience of the production process from the design stage

- Adopting the international advanced quality management system, strict management of IQC, production and QA

Effective Communication and Collaboration

- Customer needs analysis team respond to customer quickly and professionally

- Professional sale engineers provide one-stop customized services

Professional R&D engineer team work for you

From developing&research, prototype, testing, small batch test, mass production and after-sales service

Start the Custom Service for Your Square Gear Motor

Requirements discussion

To ensure providing the best solution of DC gear motor, the sales engineers should discuss with customer some important infomation including:

- The installation dimension for DC gear motor

- The parameter for DC gear motor includes operation load speed, operation load torque, voltage, output load current,stall torque, stall current, work cycle, working condition, noise level, lifetime,Electromagnetic shielding, etc

- The certification requirements, such as CE, ROHS, SGS, TEACH.

- The target cost and project plan.

Project Evaluation

According customer’s requirments for DC gear motor and other information of project, our R&D team analyst and evaluate the project. And to confirm provide our exsiting solution or build a new solution. If to design a new DC gear motor, DONGMING design team will provide the project evaluation report for the development time, mold cost and risk.

Prototype sample manufacturing

To confirm all requirements with customers step by step, our R&D will utilize the design software to design a product or set a 2D/3D drawing for DC gear motor.

Sample performance test

When the sample is completed, our R&D team will test the DC gear motor’s all performance with our precise test equipment. If customers have lifetime requirement, we will provide the lifetime cycle test in laboratory.

Small batch production and mass production

Start a trial production after sample working perfectly on product. Launch small batch to test customers’ market.

Finally start the mass production

We have the compeleted quality control system for production.

Delivery and after-sales service

When products ready to ship, we are also responding for logistics to make sure customer picks up all products satisfied.

If customers have any issue after sales, our team will support to solve it always.

DC Motor Types

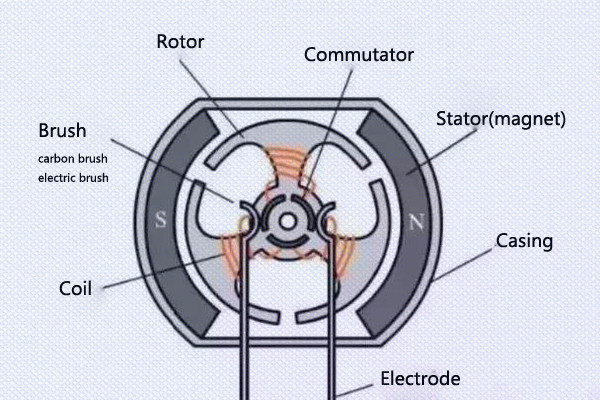

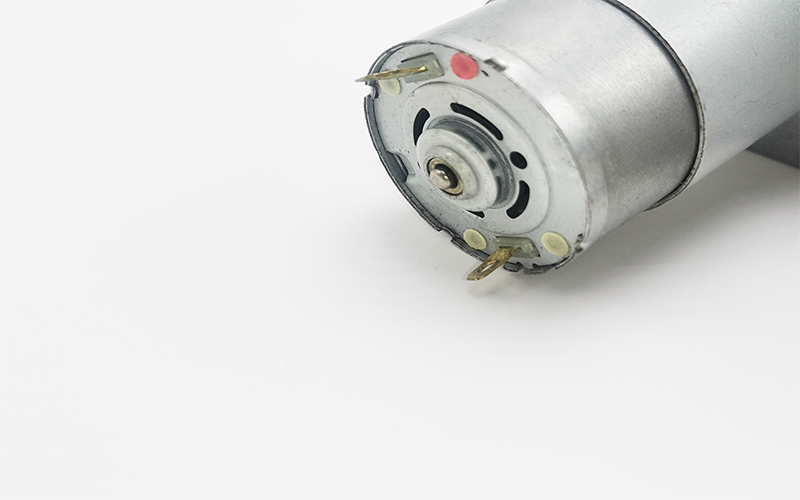

Brushed DC Motor

Brushed DC motors work by having the coil rotate inside the surrounding magnets. The rotation of the coil causes the contact between commutator and brush to alternate, therefore switching the current flow through the coil. As a result, the brushed DC motor can operate.

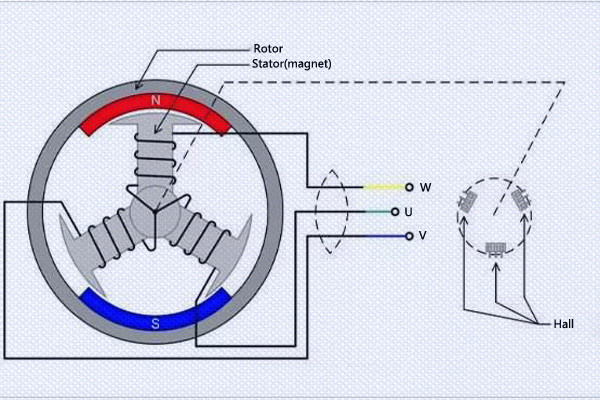

Brushless DC Motor

A Brushless DC Motor (BLDC) is an electric motor powered by a direct current voltage supply and commutated electronically instead of by brushes like in conventional DC motors. BLDC motors are more popular than the conventional DC motors nowadays, but the development of these type of motors has only been possible since the 1960s when semiconductor electronics were developed.

Gearbox Types

Spur Gearbox

Spur gears are used in mechanical applications to increase or decrease the speed of a device or multiply torque by transmitting motion and power from one shaft to another through a series of mated gears.Spur gears are more efficient compared to helical gears with the same size. They are quite reliable and offer constant velocity. Spur gears are also considered a member of positive transmission because they don't have any slippage

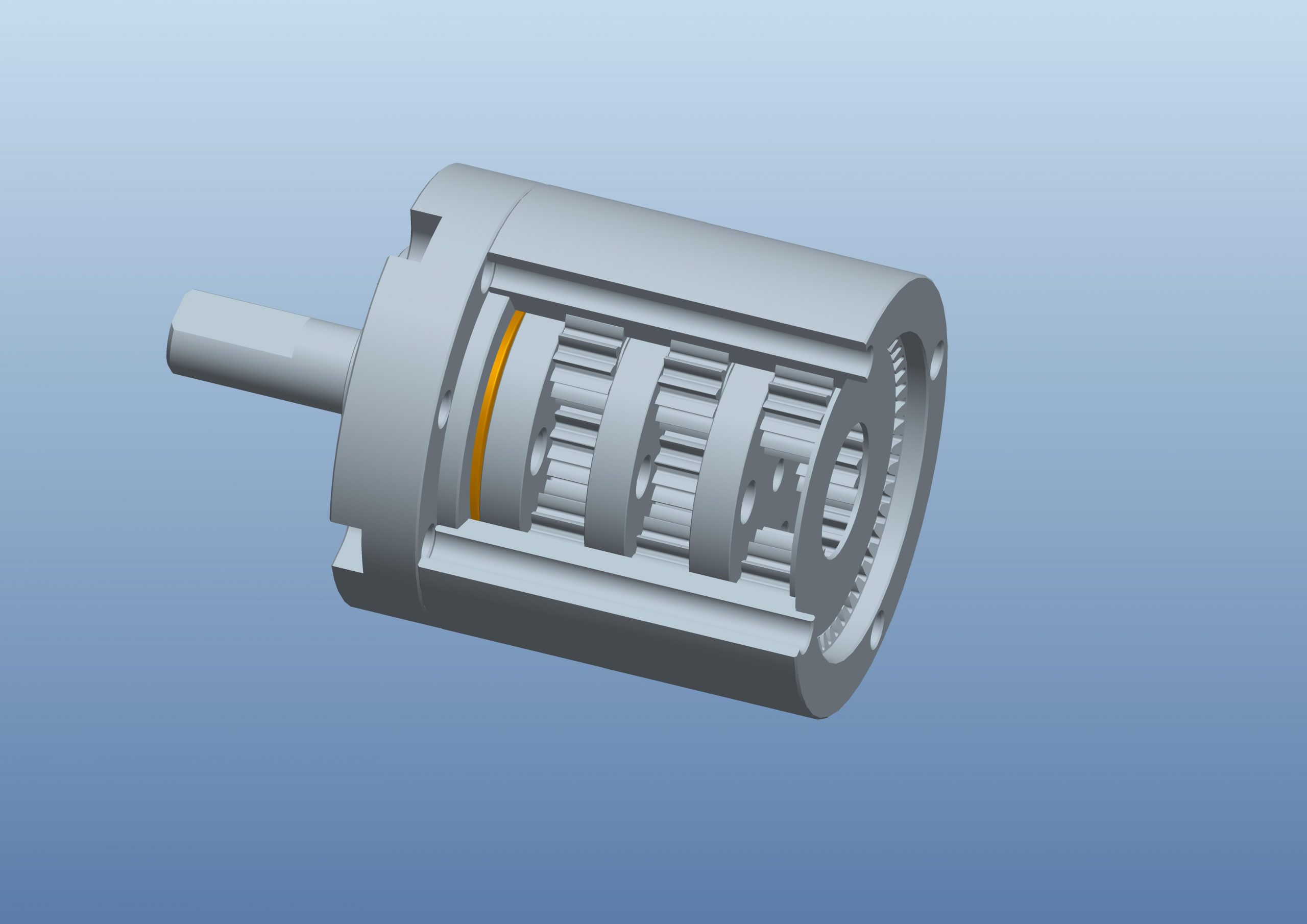

Planetary Gearbox

A planetary gearbox is a gearbox with the input shaft and the output shaft aligned. A planetary gearbox is used to transfer the largest torque in the most compact form (known as torque density).Planetary gear systems are able to produce a lot of torque because the load is shared among multiple planet gears. This arrangement also creates more contact surfaces and a larger contact area between the gears than a traditional parallel axis gear system.

Worm Gearbox

Worm gears operate by the friction created by turning lubricated gears. The friction is then converted into heat. By producing a low speed and high-speed torque level, worm gears are utilised as speed reducers, which implies that they are ideal for several applications. In theory, a worm gear is self-locking when the static friction angle is larger than the helix angle of the worm. The static friction angle is described as the angle where the load above will start to move.

Applications

Robotics

From robotic arms to teaching robotics and robotic toys, square gear motors play a crucial role in facilitating precise and controlled movements.

Sanitary Automations

In dispensers, lid openers, and sensor sanitary bins, square gear motors contribute to the seamless functioning of sanitary automation systems.

Safe and Security Systems

Electronic locks, door locks, safes, and latch closers benefit from the reliability and efficiency of square gear motors.

Valve/Meter Mechanisms

Electric valves, gas meters, and water meters leverage square gear motors for optimal performance.

Curtain Automation

Electric curtains and blinds are enhanced with the controlled and efficient movement provided by square gear motors.

Coffee Machines

In the realm of coffee machines, including coffee makers and bean grinders, square gear motors ensure precise and reliable operations.

Pet Care Devices

From anti-bark devices to pet feeders and door openers, square gear motors contribute to the comfort and well-being of our furry friends.

Bank Automation

ATMs, coin counters, coin selectors, coin validators, and banknote counters benefit from the precision and durability of square gear motors.

Vending Machines

Beverage vending machines, hot and cold drink dispensers, and juicer makers rely on the efficiency and reliability of square gear motors.

Medical Care Equipment

Diagnostic equipment, medical beds, massagers, and beauty care appliances are empowered by the precision movements of square gear motors.

Others

From BBQs and 3D printing to baby cradles, fish feeders, humidifiers, and range hoods, square gear motors find applications in a diverse array of industries and products.

Square Gear Motor Guide

Square Gear Motors Advantages

The square gear motor Motor, with its distinctive design combining a DC motor and a square gearbox, offers several advantages to various customer applications. In addition to increasing the gear ratio, it also manages to conserve space, which is a priceless feature in today’s streamlined and compact systems. This motor’s defining feature is its square gearbox, which greatly enhances its exceptional performance.

There are many advantages of using the square gearbox but the biggest advantages are:

- Low-Speed Capabilities: One of the standout features of the square gear motor is its impressive range of low speeds. Operating at speeds as low as 1RPM to 160RPM, with most variants comfortably below 50 rpm, this motor is adept at delivering precise and controlled movements. This characteristic makes it ideal for applications requiring slow and accurate motion, such as robotics, automated systems, and intricate machinery.

- High Torque Output: Another key advantage offered by the square gear motor is its ability to generate substantial torque. With torque levels reaching up to an impressive 300 kilogram-centimeters (kg.cm), this motor is capable of handling demanding tasks that require significant rotational force. The flat gear motor’s high torque output ensures optimal performance in diverse industrial applications.

- Convenient Flat Shape: The design of the square gear motor features a flat shape, which facilitates easy mounting for various applications. Its compact and streamlined structure makes it highly adaptable to constrained spaces and allows for efficient integration into complex systems.

These advantages are great but the square Gear Motor is not without its disadvantages. Its biggest disadvantage is the comparatively higher noise it produces compared to other DC gear motor types. The gear interaction within the flat gearbox can generate audible vibrations, resulting in an increased noise output. While this may not be a significant concern in certain applications, it is essential to consider noise levels when implementing the flat gear motor in noise-sensitive environments or applications where quieter operation is desired.

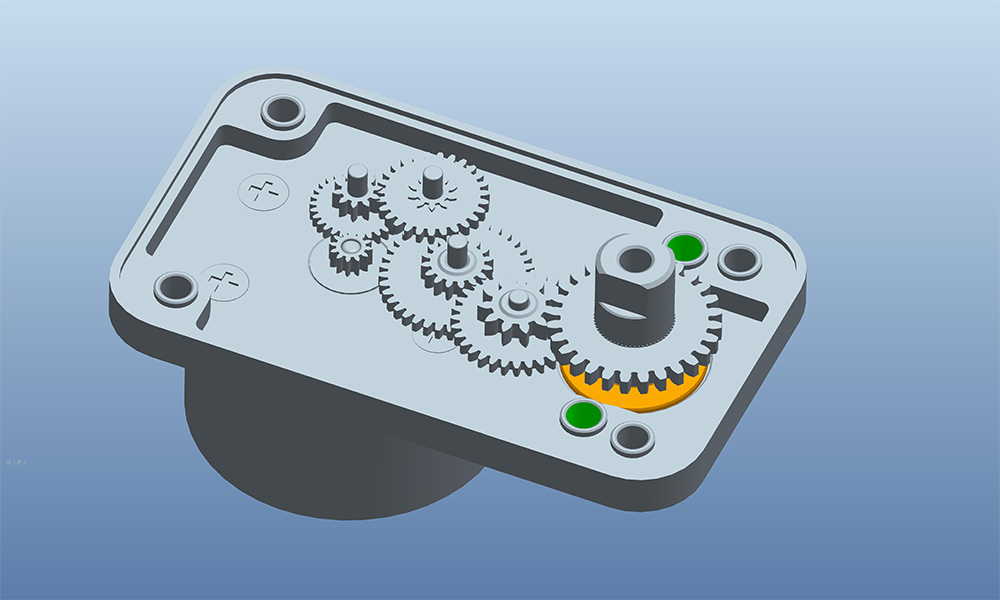

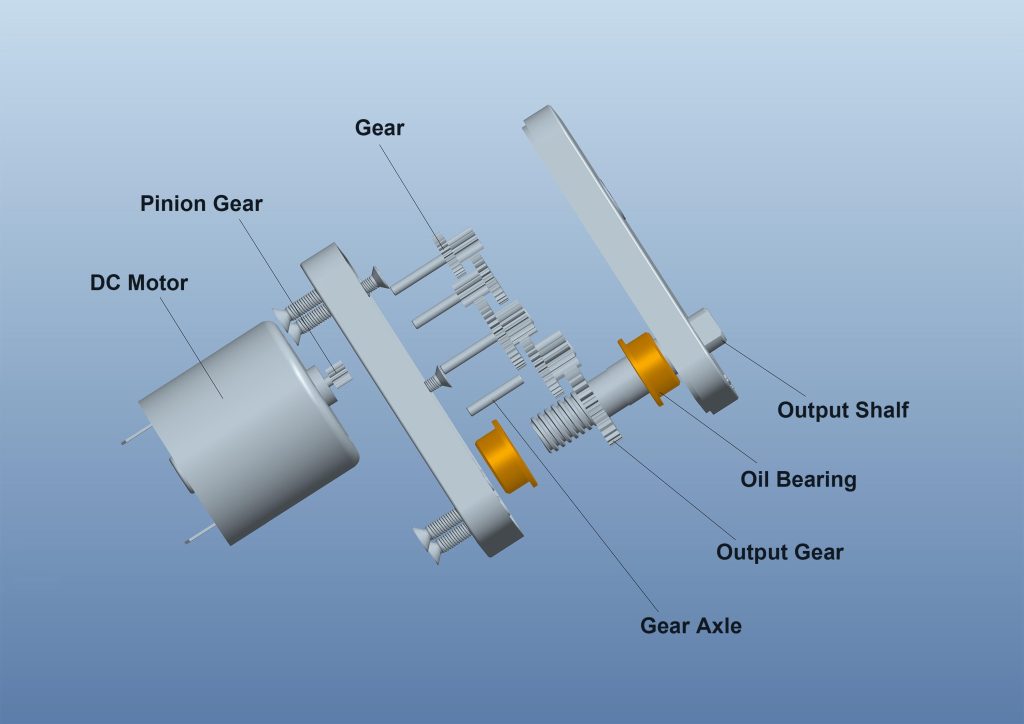

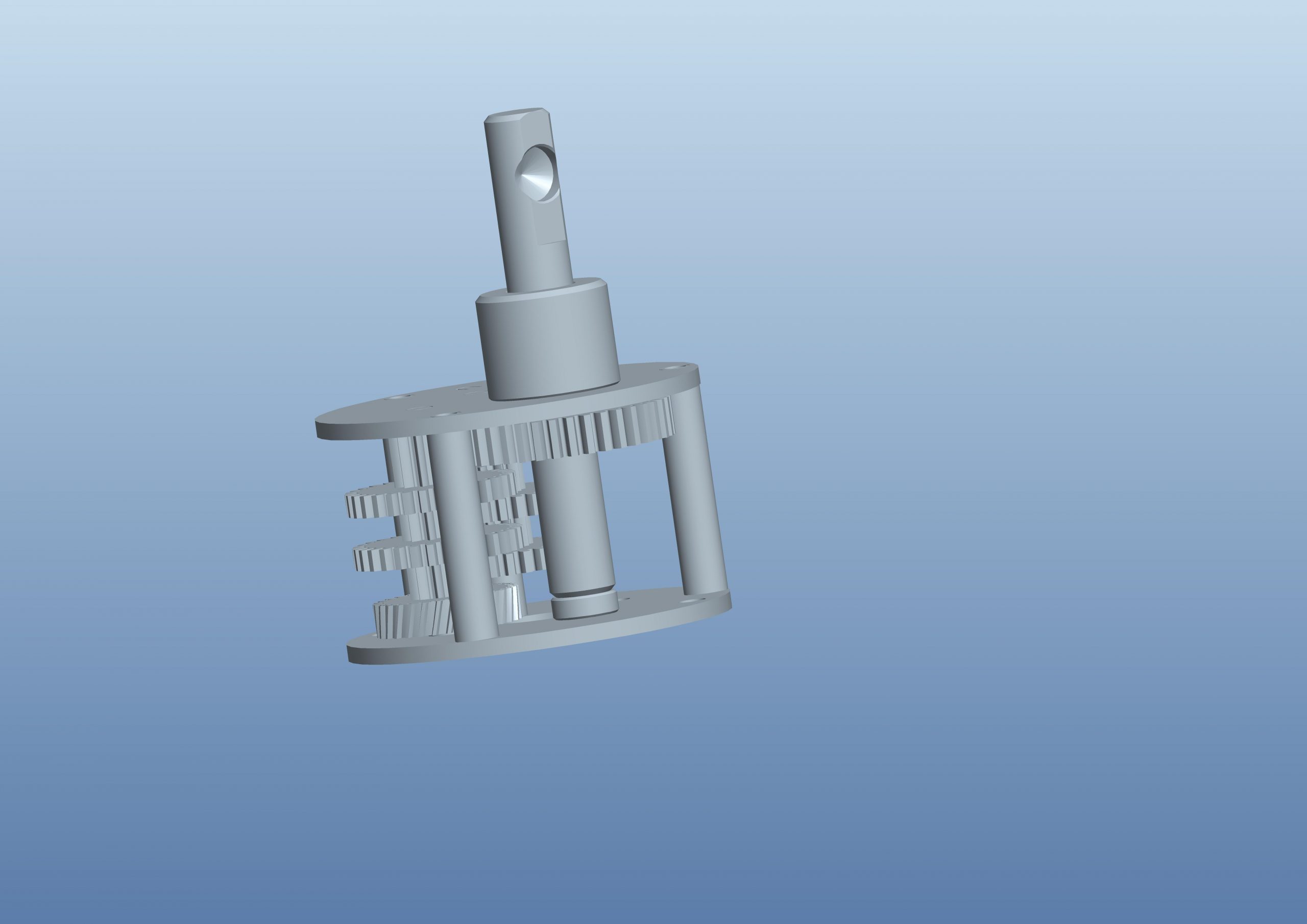

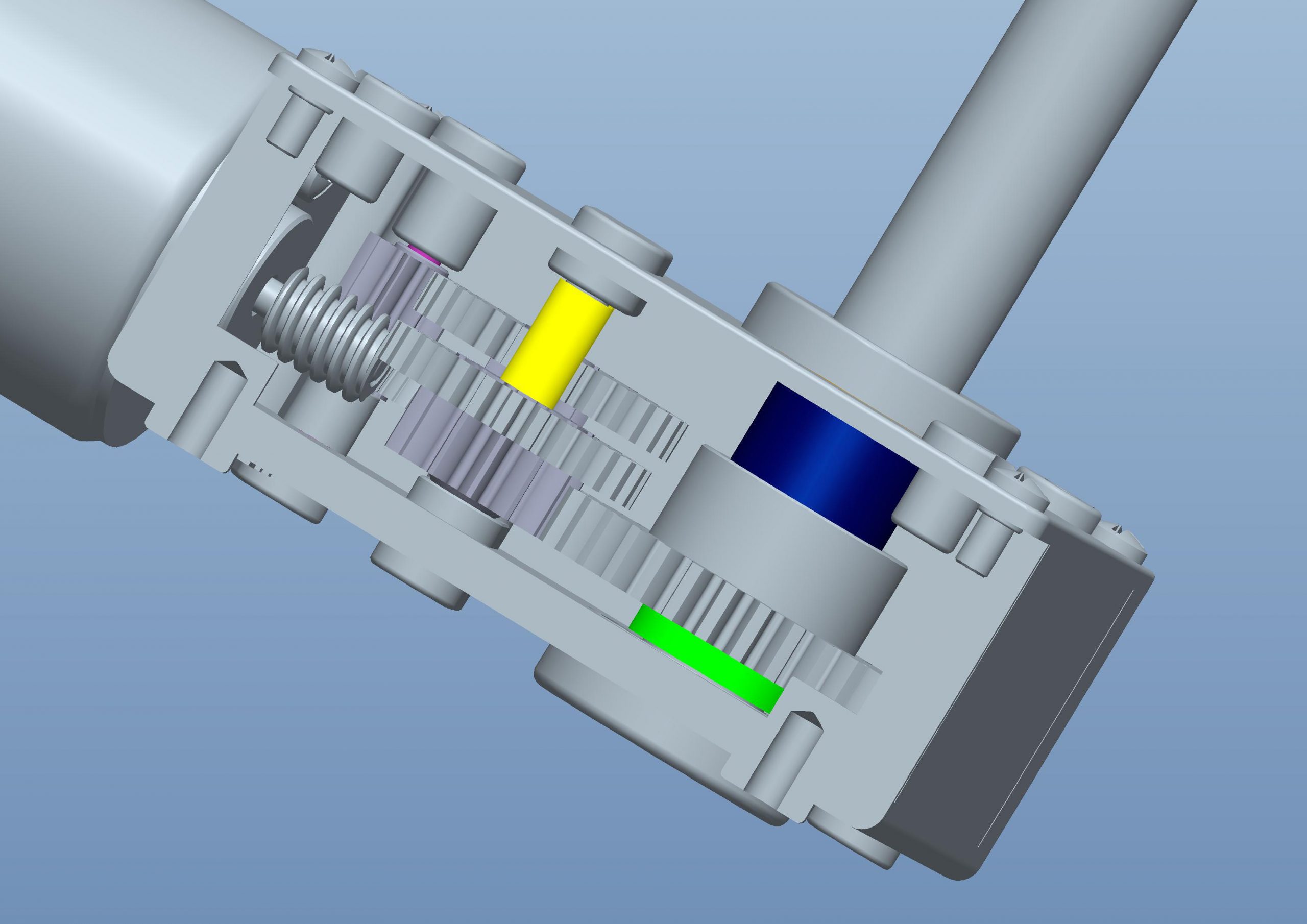

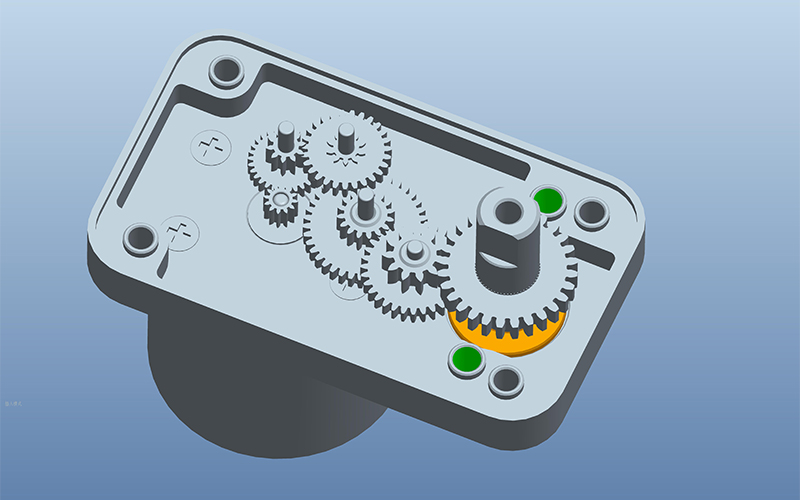

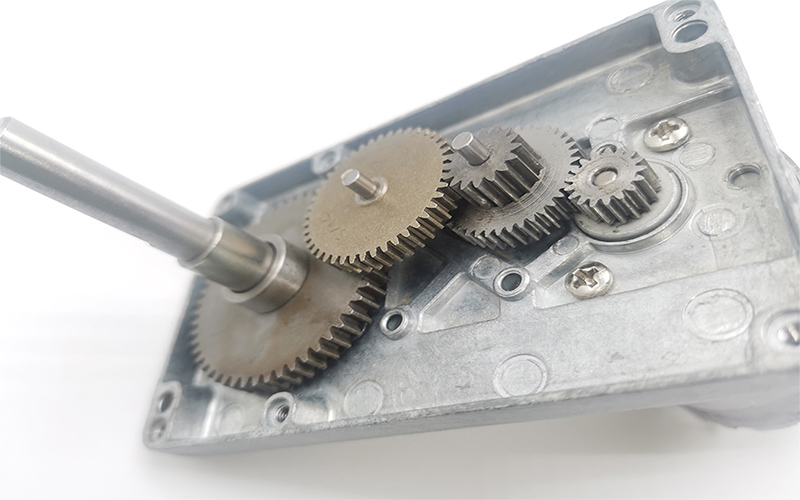

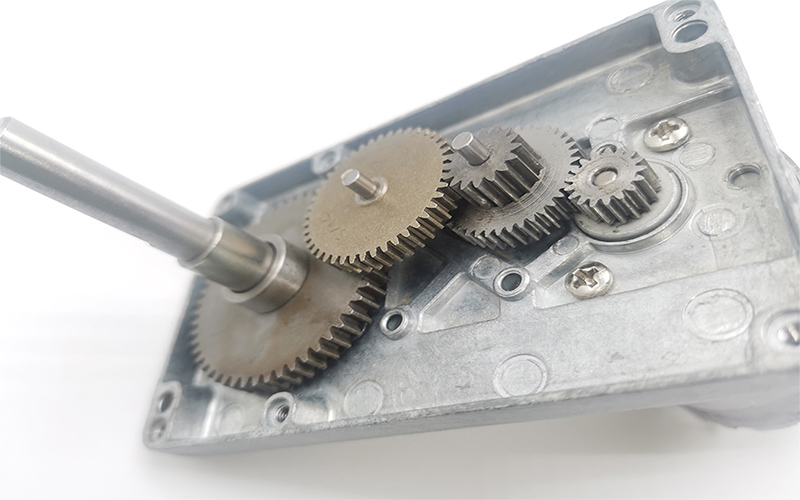

What is the Structure For Square Gear Motor?

The structure of a square gear motor comprises several essential components that work synergistic-ally to enable its efficient operation and deliver reliable performance. While variations may exist among different manufacturers and models, the following key elements are typically found in a square gear motor:

Motor: Positioned at the core of the square gear motor is an electric motor, commonly a DC (direct current) motor. This motor serves as the primary power source, converting electrical energy into mechanical energy. By harnessing the principles of electromagnetism, it generates rotational motion that drives the entire gear system.

Gear System: The square gear motor showcases a meticulously designed gear system, which plays a pivotal role in transmitting and manipulating the rotational motion produced by the motor. This system comprises an assortment of gears, including spur gears, helical gears, arranged in a square or rectangular formation. Each gear within the system serves a specific purpose, such as speed reduction, torque amplification, or direction change, depending on the application requirements.

Gearbox: A crucial component of the square gear motor is the gearbox. This housing encloses the gear system and provides mechanical support, ensuring precise alignment and smooth operation of the gears. The gearbox may be constructed from durable materials such as stainless steel or aluminum alloy, offering excellent structural integrity and protecting the internal gears from external contaminants or damage.

Bearings: To facilitate smooth rotation and minimize frictional losses, square gear motors often incorporate high-quality bearings: oil bearing, ball bearing. These precision-engineered components are strategically positioned within the gearbox, supporting the rotating shafts and reducing wear and tear. By enabling smooth and efficient motion, bearings contribute to the overall longevity and reliability of the motor.

Mounting Arrangement: Square gear motor are designed with practicality in mind, featuring a mounting arrangement that facilitates easy installation and integration into various systems.

The technical excellence and practicality of the square gear motor make it a valuable solution in a wide range of industries, including robotics, automation, manufacturing, and beyond which need high torque.

The Differences Between Square Gear Motor And Planetary Gear Motor?

Planetary gear motors and square gear motors are two different types of gear motors, each with special qualities and uses. The main variations between the two are as follows:

Features | Square Gear Motor | Planetary Gear Motor |

Gear Arrangement | In a square gear motor, the gears are arranged in a square or rectangular configuration. The gears typically include spur gears or helical gears, which transmit motion in a straight line or at an angle. The square gear motor arrangement allows for efficient power transmission. | In a planetary gear motor, the gears are arranged in a planetary or cyclic system. The gears consist of a central sun gear, surrounded by multiple planet gears that mesh with an outer ring gear. This arrangement offers high gear reduction ratios and exceptional torque output. |

Gear Reduction | Square gear motors typically provide moderate gear reduction ratios, which are suitable for applications that require a balance between speed and torque. They offer reliable torque amplification and adequate speed reduction for various industrial and commercial uses. | Planetary gear motors excel in providing high gear reduction ratios. The planetary gear arrangement enables multiple gear stages, allowing for significant torque multiplication while maintaining a compact size. |

Efficiency and Precision | Square gear motors generally exhibit good efficiency and reliability. They offer reliable power transmission with minimal backlash and are capable of delivering consistent performance over extended periods. However, their efficiency may be slightly lower compared to planetary gear motors. | Planetary gear motors are renowned for their exceptional efficiency and precise motion control. The gear design minimizes backlash and ensures accurate positioning, making them ideal for applications that require high precision and repeatability. |

Application Focus | Square gear motors are commonly used in various applications, including conveyor systems, packaging machinery, material handling equipment, and low-speed rotational systems. They are suitable for applications that prioritize compactness, simplicity, and moderate torque requirements. | Planetary gear motors are widely employed in robotics, automobile, medical equipment, aerospace technology, and other applications that demand high torque, precise motion control, and compact design. |

How the Square Geared DC Motor Works?

The square geared DC motor operates by utilizing the principles of mechanical power transmission through a system of gears. Here’s an easy-to-follow breakdown of how a square gear motor generally operates:

1.The square geared DCmotor receives electrical power input from an outside power source, typically in the form of direct current (DC). This electrical energy is transformed inside the motor into mechanical energy.

2. Thesquare geared DC motor’s electric motor transforms electrical energy into rotational motion. A stator with wire windings serves as the motor’s stationary component, along with the rotor, which rotates. An electromagnetic field is produced when an electric current is run through the windings, which causes the rotor to rotate.

3. The gear system receives the rotational motion produced by the motor. A set of gears, usually spur gears or helical gears, are arranged in a square or rectangular pattern by thesquare geared DC The gears mesh together and make contact with one another, transferring rotational force and torque.

4. The gear system transmits the rotational motion of the motor, and the gears work together to either increase or decrease the output speed and torque. The degree of reduction or amplification is determined by the particular gear arrangement and ratios. To balance speed and torque, square gear motors typically offer moderate gear reduction ratios.

5. The output shaft of the square geared motor is connected to the final gear within the gear system. As the gears rotate, the motion is transferred to the output shaft. This shaft extends from the motor housing and delivers the rotational output to the external mechanical system or load.

6. The rotational output from thesquare geared DC motor is utilized to drive or operate the intended load or mechanical system. The load can differ significantly depending on the particular application. It might entail maneuvering machinery, rotating arms, or any other activity requiring precise and controlled rotational motion.

Throughout this process, the square geared motor ensures efficient power transmission and reliable performance.

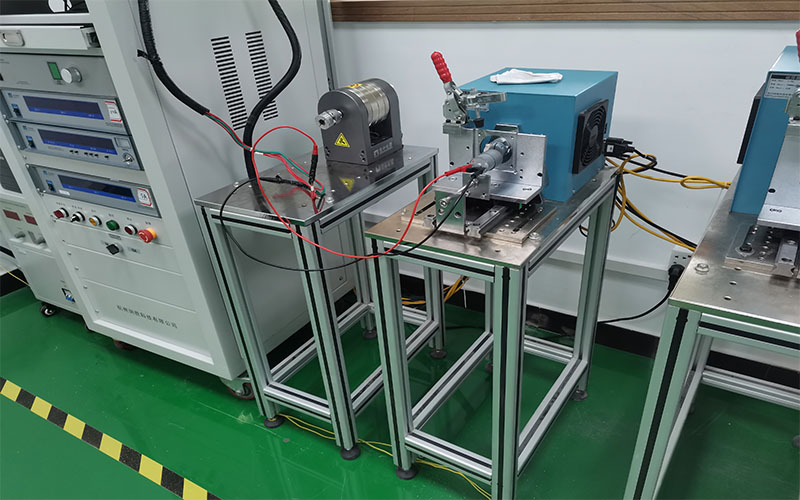

How Do You Test a Square Geared Motor?

Testing a square geared motor involves assessing its performance, functionality, and reliability. Here are the general steps involved in testing a square geared motor:

1. Visual Inspection:

Examine the motor for any visible damage, loose connections, or signs of wear. Ensure all components are securely fastened and look for corrosion or overheating.

Dimension Inspection:

Begin by conducting a thorough dimension inspection of the square geared motor. Measure the dimensions of critical components such as the output shaft, gearbox width, gearbox length, DC motor dimensions, and any other relevant parameters. Ensure that the dimensions meet the required specifications and match the intended application.

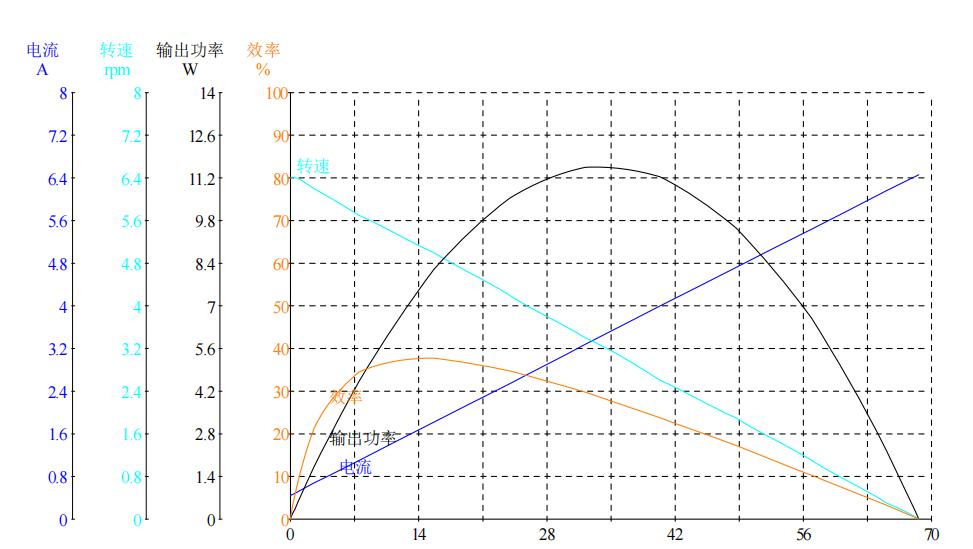

Load Performance Test by Dynamometer:

The load performance test is crucial to evaluate the motor’s performance under different operating conditions. Using a dynamometer, perform the following tests:

- No Load Test:Measure the motor’s speed and current when it is not driving any load. This test provides insights into the motor’s unloaded performance.

- Rated Performance Test:Determine the motor’s performance at its rated speed and torque. Measure the speed, torque, and current at this point to ensure they align with the motor’s specifications.

- Max Efficiency Point Test:Identify the operating point at which the motor delivers the highest efficiency. At this point, gauge the input power, speed, torque, and current.

- Max Power Test:Measure the motor’s current, speed, torque, and input power at this operating point to ascertain its maximum power output.

4. Cycle Test for Lifespan:

Square gear motors often undergo continuous operation, making it crucial to assess their lifespan and durability. Perform a cycle test by subjecting the motor to a series of operational cycles, simulating real-world usage. This test involves running the motor continuously for an extended period or through a predefined number of cycles. Monitor the motor’s performance, temperature, and any signs of wear or deterioration during the test.

It’s important to refer to the manufacturer’s guidelines and specifications when testing a square geared motor, as they may provide specific instructions or recommendations for the testing process.